Cutting Out the Cracks: Advantages of Thermal Stress Cutting

Over the past five years, cutting solar cells in half has grown to become a mainstream strategy in PV manufacturing, having demonstrated significant gains in both power rating and mechanical strength at module level. It is also one of the key developments that has allowed the recent switch to larger cell formats and the accompanying jump in module power ratings. And since many of these larger formats, as well as other technologies that caught the eye of manufacturers, require cells to be cut into three or even more pieces, cell cutting is sure to remain at the heart of PV manufacturing for the foreseeable future.

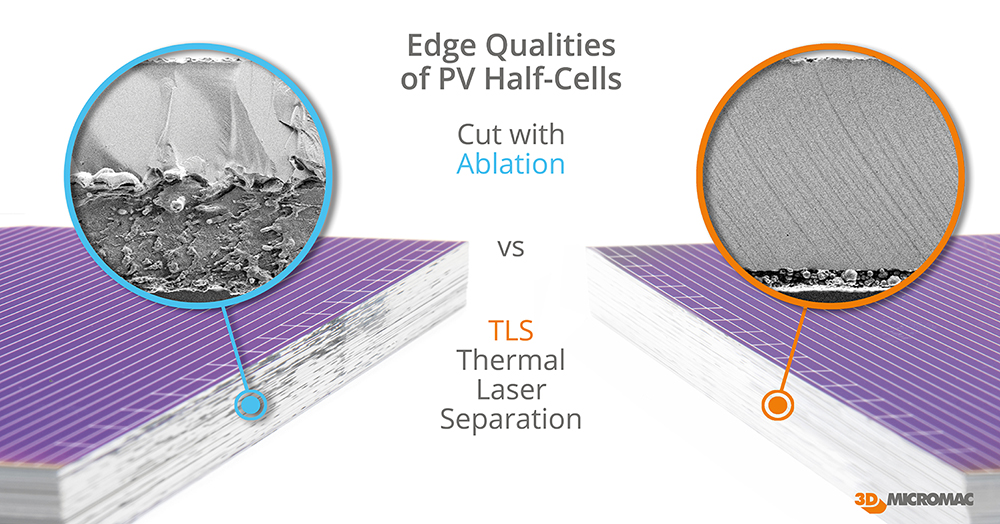

But this has not come without challenges or risk. Many conventional cutting processes place can leave damage and microcracks – which can grow to affect performance further down the line – along the cut edge of the cell.

Webinar Content

- Thermal Laser Separation – Fundamentals and technology explanation

- Investigation of cutting-related electrical losses

- Comparison between TLS and laser scribing and mechanical cleaving processes

- Impacts in commercial production

- Q&A: Questions can be submitted beforehand or during the webinar through a chat window.

In this pv magazine Webinar produced in partnership with 3D-Micromac, the German equipment supplier introduces its Thermal Laser Separation process, which breaks the cell using an innovative laser heating / water cooling process that promises to leave a clean edge with no microcracks. Thomas Kießling, Senior Product Expert at 3D-Micromac will take us through the fundamentals of the process, and its advantages both technological and economic.

We’ll then take a deeper dive into the technology with Fraunhofer ISE’s Puzant Baliozian, who will present the institute’s latest results from cells cut using the TLS process, and a comparison with the conventional scribe and break processes.

Finally, we hear from French module manufacturer Voltec Solar, which has implemented the TLS tools in its production lines. Thomas Regrettier, Voltec’s R&D Manager, shares his experience of running the process at scale, at the advantages to be found in the end product.