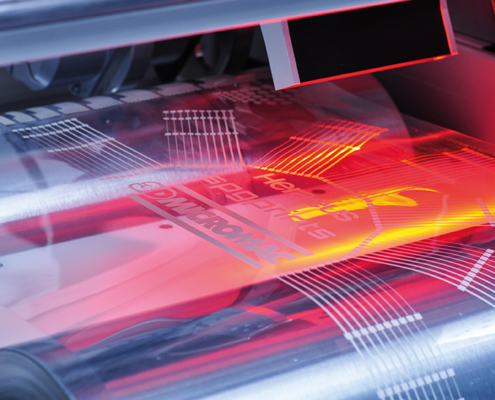

Roll-to-Roll Laser Processing of Flexible Devices

In the manufacturing of flexible thin-film devices precision, throughput, and machining quality on ever-smaller structures are playing an important role. This webinar will give you a brief overview of different case studies where roll-to-roll laser processing achieved new dimensions in terms of precision, quality and process efficiency.

One example application is the ablation of thin-film layers for medical sensors. In this case, the on-the-fly laser ablation takes place by using an excimer laser and mask projection. The layout of the products is adaptable by various projection masks. The high-repetition rate of the excimer laser allows the production of up to 150 sensors per second.

After this webinar you will be well-informed about:

- The driving forces behind the processing of flexible devices

- The requirements on production equipment for flexible devices

- Why laser micromachining and roll-to-roll processing go hand-in-hand

- The benefits of 3D-Micromac’s microFLEX platform

- How medical sensors can be manufactured with microFLEX laser systems

- How rare materials can be saved while ablating sensors

This webinar will be recorded and the recording will be shared with all registrants afterwards.